There are a lot of challenges when working on silver. Let us explain:

To begin, it is important to understand that when you are soldering a piece of jewelry, you are not melting solder onto or into the piece, but rather heating the piece you want to solder to the point that it causes the solder to melt.

Silver makes soldering very difficult because it conducts heat so well (meaning, the heat spreads throughout the piece very quickly). Consequently, you cannot keep the heat local to where you want to solder, which becomes very problematic when you take into account that you may need to heat the ring to 1475 degrees to get the solder to flow (melt). Obviously, if the ring has any gemstones in it, this can be a huge problem.

Another challenge with silver is that the piece needs to be clean before the solder will flow. The trouble is that the very act of heating it also makes it dirty. The oxygen in the air is only too eager to oxidize everything it touches, and, as far as solder is concerned, metal oxide is dirt. As most of you know, silver oxidizes easily.

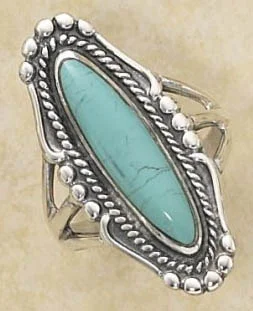

Add to the above that we are frequently surprised by what we discover when working on silver. Over the last number of years we have found "silver" pieces heavily plated with metals such as chrome, as well as heavily plated copper marked "Sterling". Additionally, rings, such as the one pictured above, often have a support material underneath the stone, such as cardboard or sawdust. The list goes on.

Consequently, it's often easier to just say "no".

Probably smarter too.